Resources to Improve Your Extrusion Designs

Looking for information on aluminum extrusion design and manufacturing? Our resource library offers several free informative guides, technical data sheets, and helpful information for you to download and use.

Aluminum Extrusion Design: 7 Decisions that Increase Your Die Tooling Costs

Detailed guide addresses seven factors that impact the cost of an extrusion die and offers tips to save time and money.

3 Toughest LED Lighting Design Challenges Solved Using Aluminum Extrusions

Read how aluminum extrusions can help LED lighting designers & manufacturers build more reliable, efficient & cost-effective fixtures.

Choosing the Right Finish for Your Aluminum Extrusion Profile

Learn about the different surface finishing techniques for aluminum extrusion profiles and how to choose the best finish to enhance, protect or prep your component.

Precision Beyond Standards: 9-Year Partnership Delivers Complex Medical-Grade Linear Motion Solutions

Custom Aluminum Extrusion Gallery

Aluminum extrusions offer designers endless possibilities to create the shape they desire and integrate multiple functions into one profile. Custom extrusions can easily incorporate built‐in hinges, screw bosses, receptors, and grooves, and can integrate assembly options such as a built‐in dovetail, snap fit spring, and slots. Here are some examples of custom extrusions we produced.

Custom Accessory Rack

Our customer, a large sporting goods equipment manufacturer, had this accessory rack part originally produced in steel. Our manufacturing team was asked to replicate in aluminum and achieve the same strength requirements.

Custom Bracket

Our manufacturing team worked closely with the customer’s design team to make this custom bracket more manufacturable, reduce its production costs to fit the customer’s budget, and greatly reduce lead time for tooling.

Linear Guard Rail

Thanks to our large bed CNC capabilities (144” x 72” Komo and 120” x 60” Haas Gantry machines) we were able to produce this linear guide rail to the customer’s specific requirements.

Linear Guide Rail

This linear guide rail is a great example of how extrusion and fabrication tolerances interact in the manufacturing process.

Custom Roof Rack Rail

This component, which we extruded, cut, stamped, formed and powder coated, is an integral part of our customer’s popular roof rack system.

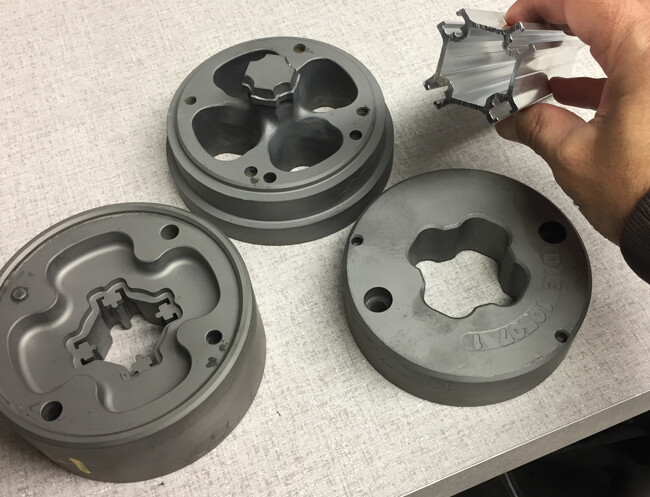

Custom Heat Sink

Extruded aluminum is one of the most popular and cost efficient heat sink methods. This custom extruded heat sink was anodizes, which slightly increases radiation of heat.

Custom Heat Sink

We produce many custom heatsinks like this one for use in electronic devices and lighting products to keep components cool.

Custom Hinge

For this custom hinged component, part of an automobile bicycle rack, we extruded, cut, mitered, stamped, machined, welded and powder coated for our customer.

Custom Bracket

This custom component was extruded and machined for use as part of a bracket system to hold an antenna.