We’re committed to providing Contract Manufacturers, OEMs, and Original Product and Design Manufacturers with the most cost-effective and efficient manufacturing solution for custom aluminum profiles and manufactured aluminum parts and components. See for yourself why we’re a leading manufacturing partner.

Aluminum Extrusion Manufacturing that Improves Your Bottom Line

Cost-Effective Manufacturing: Investments in a fully automated aluminum extrusion production line, automated handling equipment, and multi-function machining equipment keep our production costs low and allow us to pass on savings to our customers.

Reliable Performance: Two state-of-the-art extrusion production lines and duplication of critical machining and fabrication equipment both in-house and across the MMG business enable us to respond quickly to shifting customer supply needs and ensure we remain an efficient, reliable manufacturing partner.

Supply Chain Efficiency: Our in-house aluminum component machining, fabrication, surface finishing, parts assembly, packaging, and fulfillment solutions can be used to further reduce your costs and accelerate your time to market.

Customer-First Approach: Finally, we strive to improve our customers’ bottom line by proactively suggesting ways to reduce production costs, including design for manufacturing support, alloy and temper strategies, and machining/fabrication options.

Request an Aluminum Extrusion Manufacturing Quote

Have a new product or project? Are you looking for an aluminum extrusion manufacturing partner? Interested in comparing us to your current extrusion supplier? Complete our online form for a no-obligation estimate.

Over 35 Years of Aluminum Extrusion Manufacturing Expertise

With over three decades of experience supporting regional, national, and global companies, many of whom have been with us for 20+ years, we know what it takes to be a trusted supply chain partner. As a U.S.-based, ISO 9001:2015 certified aluminum extrusion manufacturer, we produce extruded aluminum components that consistently meet our customers’ form, fit, function, and aesthetic requirements across many industries, including electronics, consumer products, solar energy, fiber optics, thermal management, EV components, robotics, transportation, and building products.

We look forward to the opportunity to win your business!

Our Aluminum Extrusion Capabilities

| Extrusion Presses | 2,920 ton, 8-inch diameter press line 2,750 ton, 8-inch diameter press line |

| Alloys | 1350, 6005, 6005a, 6060, 6061, 6063 |

| Extrusion Weight | 0.125 lbs. per ft. up to 7.00 lbs. per ft. |

| Quenching | High-pressure air and water quenching |

| Tempers | F / T4 / T5 / T52 / T6 / T6511 |

| Profiles Extruded | Solid / Semi-Hollows / Hollows / Multi- Hollows / Heat Sinks |

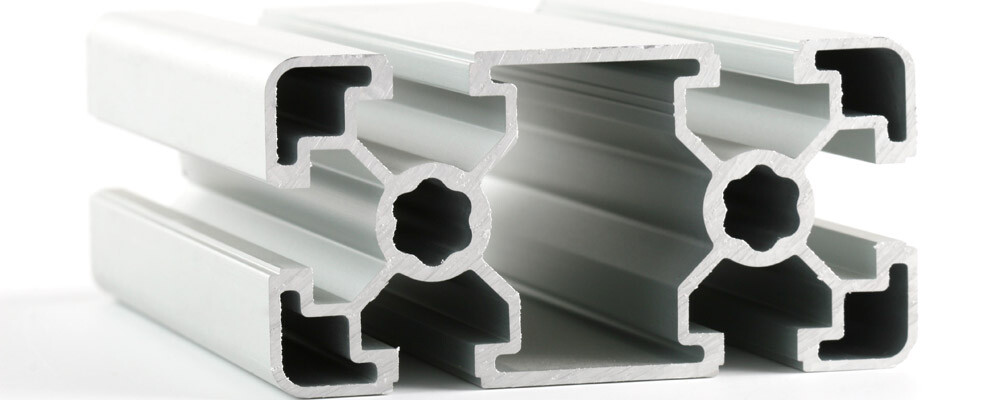

We Specialize in Manufacturing Complex, Custom Aluminum Profiles

Aluminum extrusions offer product designers endless possibilities to create a desired shape and integrate multiple functions into one aluminum profile. Custom extrusions can easily incorporate built‐in hinges, screw bosses, receptors, and grooves and can integrate assembly options such as a built‐in dovetail, snap-fit spring, and slots. We take pride in being able to produce tighter tolerances, consistent quality, and better finishes for even the most complex extruded aluminum shapes. Here are some examples of custom extrusions we produced.

In addition to our custom aluminum extrusion capabilities, we offer over 450 standard aluminum extrusion profile dies to produce a range of common shapes and sizes.