We Offer Turnkey Aluminum Extrusion Manufacturing

MMG – Engineered Extrusions is a full-service, ISO 9001:2015 certified aluminum extrusion manufacturer offering OEMs, OPMs, and Contract Manufacturers a complete manufacturing solution. Whether you need extruded components, outsourcing of crucial parts, or to launch a new product line, our extensive capabilities ensure we meet your quality, cost, and time-to-market goals.

Two state-of-the-art 8-inch aluminum extrusion presses, advanced quench systems, and precision aging ovens enable us to meet the most demanding industry requirements for custom aluminum extrusion profiles and manufactured components.

Two state-of-the-art 8-inch aluminum extrusion presses, advanced quench systems, and precision aging ovens enable us to meet the most demanding industry requirements for custom aluminum extrusion profiles and manufactured components.

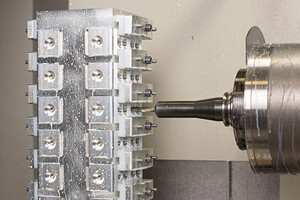

Whether you need machining services for complex prototypes, finished components, or assembled parts, MMG – Engineered Extrusions can support your needs.

Whether you need machining services for complex prototypes, finished components, or assembled parts, MMG – Engineered Extrusions can support your needs.

With over two dozen CNC machines and an experienced machining team, we provide precision machining for highly detailed extruded aluminum parts and components. We also support machining of long custom aluminum profiles over 60 inches in length, and have eight machining centers with work envelope capabilities up to 144 inches (12 feet).

Our advanced laser cutting technology replaces the need for multiple processing actions, including cutting, machining, drilling and punching, with a single laser operation. The result is faster processing and reduced production cost for aluminum tubes and custom profiles. In addition, our two laser machines can be used to cut shapes and features that can’t be made with other methods, may require extensive CNC cycle times, or multiple punch tooling investments.

Our advanced laser cutting technology replaces the need for multiple processing actions, including cutting, machining, drilling and punching, with a single laser operation. The result is faster processing and reduced production cost for aluminum tubes and custom profiles. In addition, our two laser machines can be used to cut shapes and features that can’t be made with other methods, may require extensive CNC cycle times, or multiple punch tooling investments.

If your aluminum extrusion parts or components require additional fabrication, such as precision cutting, double end mitering, milling, drilling, punching, deburring, or custom bending, we offer a complete fabrication solution.

If your aluminum extrusion parts or components require additional fabrication, such as precision cutting, double end mitering, milling, drilling, punching, deburring, or custom bending, we offer a complete fabrication solution.

Our 50,000 sq. ft. machining and fabrication center offers state-of-the-art technology and an experienced fabrication team to ensure consistent, customized quality for aluminum fabrication projects of all sizes. In fact, our extensive knowledge of aluminum alloys and fabrication expertise helps us solve challenges of working with aluminum that are beyond the capability of most machining shops.

If your part or component needs additional surface protection or an enhanced finish, we can supply powder coat, wet paint, or anodized finishes. Surface finishing is provided at our Momentum Manufacturing Group St. Johnsbury, VT and Amherst, NH locations.

If your part or component needs additional surface protection or an enhanced finish, we can supply powder coat, wet paint, or anodized finishes. Surface finishing is provided at our Momentum Manufacturing Group St. Johnsbury, VT and Amherst, NH locations.

- Aluminum Anodizing: A wide variety of colors and specifications can be obtained through partners specializing in anodizing, including organic, electrolytic and hard coating.

- Powder Coating: Numerous colors are available in polyester and epoxies, including finishes to meet salt spray requirements.

- Wet Paint: A resin-based coating provides protection against weathering, aging and pollution.

To help streamline your operations, we can assume partial or, in some cases, complete manufacturing responsibilities for components or product lines. We support various partial and finished aluminum component assembly, kitting, packaging and supply configurations. This can include packaging your product with custom labels, instructions and other items as required, then sending directly to your distributors.

To help streamline your operations, we can assume partial or, in some cases, complete manufacturing responsibilities for components or product lines. We support various partial and finished aluminum component assembly, kitting, packaging and supply configurations. This can include packaging your product with custom labels, instructions and other items as required, then sending directly to your distributors.

Our Kitting, Assembly, and Supply Capabilities Include:

- Custom, mechanical assembly systems.

- Single, multi-level and configurable bill-of-materials (BOM) assemblies.

- Customized kitting and component packaging.

- Kanban programs.

- Third party supply chain logistical management.

- Regional, national and international delivery.